The ATLANTIS Test Center infrastructure consist of

- The Coastal Testbed has a shore control room and a Floating Structure System (FSS), and it is targeted for technology developers to de-risk their robotic technologies through rigorous, cost-efficient, and staged testing programmes performed in near-real environments for a wide technical and industrial impact.

- The Offshore Testbed encompasses dedicated positions within a commercial wind farm, the WindFloat Atlantic (WFA), and it is reserved for demonstrating robotic technologies.

The ATLANTIS project introduces 4 showcases – with scenarios defined by end-users – for characterizing key areas where robotics will introduce a major contribution for the offshore wind O&M value chain.

Industry-oriented showcases for Inspection and Maintenance

1. Showcase – Turbine inspection and maintenance

1. Showcase – Turbine inspection and maintenance

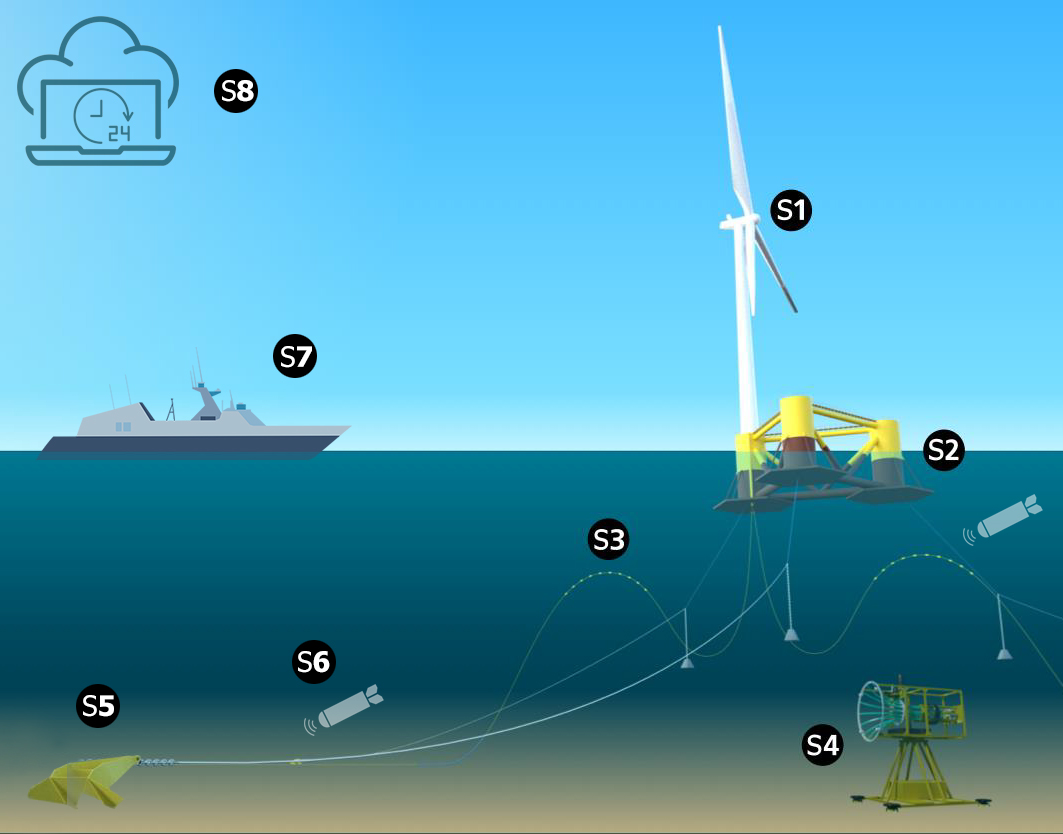

Scenario 1: Inspection of blades and tower. This scenario demonstrates the possibilities of using Unmanned Aerial Vehicles (UAVs) and Autonomous Surface Vehicles (ASVs) for Inspection and Maintenance of floating windmill tower and blades.

Scenario 2: Inspection, maintenance and repair (IMR) of the transition piece or the floating structure. This scenario demonstrates the IMR capabilities of Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs).

2. Showcase – Export cable and Array cable maintenance

Scenario 3: Repair of underwater floating wind turbine cables protection systems. This scenario demonstrates ROVs and AUVs with inspection and intervention capabilities (e.g., manipulation).

Scenario 4: Underwater monitoring over extended time periods. This scenario demonstrates AUVs and ASVs with long endurance capabilities and the use of an underwater charging station for multiday missions.

3. Showcase – Foundation and Scour protection

Scenario 5: Underwater close-range inspection of foundations. This scenario demonstrates AUVs and ROVs with close-range navigation capabilities.

Scenario 6: Underwater monitoring of scour protection interventions. Sea bed material around a fixed foundation can be removed by the action of scour. To avoid the risk of movement in these foundations, scour depth development or the effectiveness of scour protection need to be monitored routinely. This scenarios demonstrates seabed mapping with an AUV with high-level of autonomy.

4. Showcase – Offshore logistics

Scenario 7: O&M operations supported by crewless vessels. As offshore wind farms move further out to sea, demands made on supporting vessels are changing significantly to reduce the number of operators on board. Autonomous vessels have high potential to decrease personnel costs, improve response time and increase the utilization rate of a vessel. This scenario will be used to demonstrate ASV with capability to transport, deploy and recover robotic assets in real environment. Transit is simulated with a ship handling simulator.

Scenario 8: Optimization of robotic-based operations. Further challenges in optimizing these operations come from the energy perspective, propulsion usage during dynamic positioning, and from fitting the robotic unit O&M capabilities to daily operations. Metocean data recordings are used to provide real time data to support offshore activity. An O&M operation planner is developed to demonstrate these capabilities.